Release time:2023-11-12 15:29:06 Hits: Current position: Home > News

This article mainly introduces:

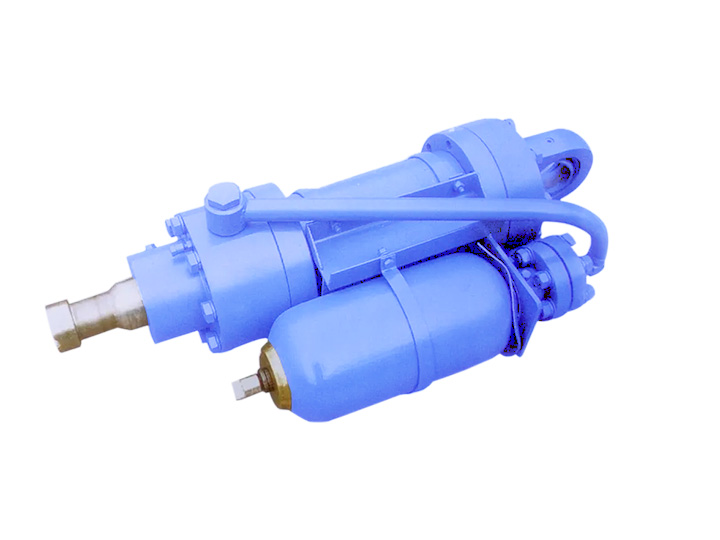

Australia hydraulic cylinder,loading cylinder manufacturer,loading cylinder

(Australia loading cylinder,produced by Hebei Hengyu company)

loading cylinder are widely used in Australia,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed loading cylinder for customers from Australia.

Disassembly loading cylinder: When disassembly loading cylinder, strictly prevent damage to the screw thread at the top of the piston rod, the screw thread of the loading cylinder head and the surface of the piston rod. It should also be noted that the piston cannot be played out from the loading cylinder.

loading cylinder piston rod material selection and requirements: ① piston rod is usually made of 45 steel. When there is a large impact force and heavy load transmission, it is made of 40Cr steel. This is to ensure that the piston rod has sufficient working strength. The piston rod is generally designed as a loading cylinder, if the diameter is larger, the hollow piston rod can be used. Made of No. 45 seamless steel pipe. ③ When the piston rod is manufactured, the blank should be first forged and conditioned after mechanical rough processing, and the hardness of HB=230 ~ 250. The purpose of conditioning is to improve the machining performance and increase the working strength of the material. ④ The surface roughness Ra of the piston rod after finishing should not be greater than 0.65μm. ⑤ In order to improve the corrosion resistance of the piston rod, the working surface of the rod can be plated with hard chromium. ⑥ The piston rod and the end cap are guided by H8 ' loading cylinder piston rod industry standard: piston rod diameter series of national recommended standard GB/T2348-1993. Piston rod thread size series standard GB/T2350-1980. Please refer to execute. There is no industry standard for piston rods Both the loading cylinder and the hydraulic motor are devices that convert the pressure energy of the liquid into mechanical energy and output it. The loading cylinder mainly outputs linear motion and force. The loading cylinder has a variety of forms, according to the different characteristics of its mechanism it can be divided into piston type, plunger type and swing type three categories, according to the mode of action he can be divided into single action and double action. Piston loading cylinder, plunger loading cylinder is mainly used for: machinery, such as excavators; Scientific research, such as university structure laboratory. The plunger loading cylinder is used for pressure testing machines, such as Jinan test, and the test machine is used for material testing.

Causes and countermeasures of oil loading cylinder leakage: Cast iron ring seal allows a certain degree of internal leakage. The impurities in the loading cylinder will lead to premature wear of the piston seal, replace the piston seal; If the loading cylinder is visibly scarred, the loading cylinder must be replaced. It can be pressurized at one end of the loading cylinder and opened at the other end of the oil port to observe whether there is obvious internal leakage at the end of the oil port. Most loading cylinder piston drift may not come from the loading cylinder, the above method to determine the loading cylinder without internal leakage is helpful to determine the problem of the hydraulic system related components.

The piston rod and guide sleeve function of the loading cylinder is crucial: the relative motion pair between the piston rod and the guide sleeve is the main factor causing external leakage, if the chrome layer on the surface of the piston rod is spalling or producing longitudinal tensile marks due to wear, it will directly lead to the failure of the seal.

What is the cylinder with rod cavity, what is the rodless cavity.

The rod cavity is the end of the piston rod, the rodless cavity is the end without the piston rod.

What is the thin cylinder used for?

The principle is no different from ordinary cylinders, that is, the installation space is small, the formation is small, and it is suitable for some special occasions. For example, the space is compact and the place of small travel is used.