Release time:2023-11-14 08:41:15 Hits: Current position: Home > News

This article mainly introduces:

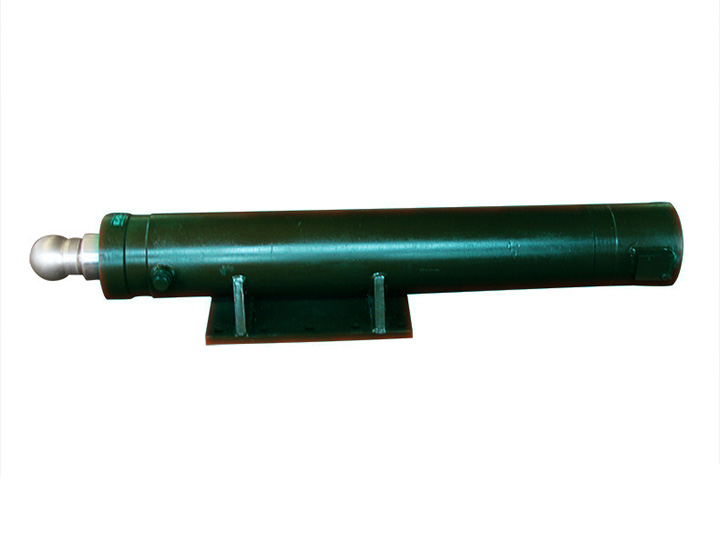

Poland hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Poland supporting cylinder,produced by Hengyu Hydraulic Cylinder Factory)

supporting cylinder are widely used in Poland,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed supporting cylinder for customers from Poland.

1, the hydraulic machinery should be kept clean, in order to prevent dust and debris from falling into the oil, the tank should be sealed. 2, the oil in the tank should be replaced regularly according to the working condition. When changing the oil, the dirt and impurities accumulated at the bottom of the tank should be removed and the tank should be cleaned. 3, hydraulic oil, oil drums should be set in a clean and safe place to strengthen management. The oil drum, oil filter, oil funnel, oil pipe, etc. used should be kept clean. The oil drums for loading hydraulic oil must be cleaned in advance, and the oil drums should be dedicated and not mixed with other oil drums.

Factors that should be considered when selecting the oil seal in the supporting cylinder: some specific factors should be taken into account when selecting the oil seal in the supporting cylinder, so as to have correct consideration and get accurate results, and then avoid wrong selection. The factors and aspects that should be taken into account are eight: supporting cylinder diameter, piston rod diameter, piston rod and piston groove size, supporting cylinder working pressure, supporting cylinder movement speed, hydraulic system oil temperature and supporting cylinder working environment.

Before the supporting cylinder is removed, the relief valve should be loosened to reduce the pressure of the hydraulic circuit to zero, and then the power supply should be cut off to stop the hydraulic device. After loosening the oil port piping, the oil plug should be applied to plug the oil port.

The repair method of supporting cylinder wear: 1. Metal repair material is applied to the scratched surface; The first layer should be thin, uniform and fully covered with the scratched surface to ensure the best adhesion between the material and the metal surface, and then apply the material to the entire repair site and press repeatedly to ensure that the material is filled and reaches the required thickness, so that it is slightly higher than the surface of the guide rail; 2, the material at 24℃ to fully achieve the performance of 24 hours, in order to save time, can be through the tungsten halogen lamp to increase the temperature, the temperature rises 11℃, the curing time will be reduced by half, the best curing temperature 70℃; 3. After the material is cured, use a fine grinding stone or a scraper to repair and smooth the material higher than the surface of the guide rail, and the construction is completed.

What do cylinder internal leakage and external leakage mean?

Internal leakage means that the piston seal in the cylinder is not strict, there is a leak between the two chambers of the cylinder, the oil is still in the cylinder, and the external leakage is that the oil leaks to the outside of the cylinder.

Need a hydraulic cylinder, vertical upward 10 seconds to lift 20 tons of weight up 2 meters, how large cylinder and rod, how much pressure to use the plunger pump and how big?

The first thing to determine the system pressure, let's say 25 mpa, can take into account cost and performance. 1 Cylinder area 20000/250=80 square cm cylinder diameter (80/3.14) squared x2=200 mm 2 cylinder volume 80x200=16000 ml =16 L 3 Required pump flow 16x60/10=96 L/min 4 Power 96x25/55=43 kW 45 kW motor is available.