Release time:2023-11-08 08:11:56 Hits: Current position: Home > News

This article mainly introduces:

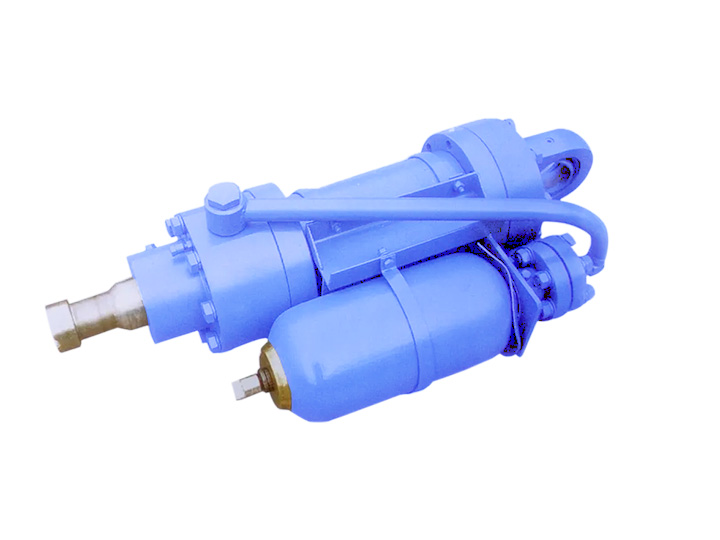

Hungary hydraulic cylinder,loading cylinder manufacturer,loading cylinder

(Hungary loading cylinder,produced by Hengyu Hydraulic Co., Ltd)

loading cylinder are widely used in Hungary,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed loading cylinder for customers from Hungary.

The loading cylinder should not be mixed with foreign objects during assembly, which will cause scars. Before the total assembly of the loading cylinder, all parts must be fully removed and cleaned. When the parts are installed with burrs or dirt, foreign objects are easily embedded into the surface of the loading cylinder wall due to the stiffness and the weight of the parts, causing scars.

The commonly used buffer structure of the loading cylinder is composed of a piston boss and a loading cylinder head groove. When the piston moves close to the loading cylinder head, it gradually enters the groove, and the oil in the groove is extruded through the gap between the boss and the groove, which increases the oil return resistance, produces the braking effect and realizes the buffer. Generally, a buffer mechanism should be used when the pressure is above 10MP.

When the control pressure of the hydraulic system is too low, the loading cylinder will appear wrong or no action, because the throttle resistance in the control pipeline may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is interfered with. At this time, check the control pressure source to ensure that the pressure is adjusted to the specified value of the system.

loading cylinder to reasonable use of hydraulic oil: strict hydraulic oil selection off. Hydraulic oil is selected in strict accordance with oil standards. The selection of good quality hydraulic oil can effectively prevent bubbles in the working process of the hydraulic system. When choosing the oil, it should be selected according to the lowest temperature in different regions, and fill the hydraulic oil according to the dipstick standard, and at the same time, it should also keep the hydraulic system clean (when filling the hydraulic oil, it should prevent the water and other impurities into it), and often check the oil quality, oil level and oil color of the hydraulic oil. If blisters and bubbles are found in the hydraulic oil. When the oil becomes milky white, the source of the air in the oil should be carefully found and eliminated in time.

How to remove the cylinder correctly?

(1) Before disassembling the hydraulic cylinder, the hydraulic circuit should be depressurized. Otherwise, when the tubing joint connected with the cylinder is loosened, the high-pressure oil in the circuit will be quickly ejected. The hydraulic circuit of the hydraulic press should first loosen the hand wheel or pressure regulator screw at the relief valve, so that the pressure oil is unloaded, and then block the power supply or block the power source to stop the operation of the hydraulic equipment. (2) When disassembling, it should prevent damage to the top thread of the piston rod, the oil thread, the appearance of the piston rod, the inner wall of the cylinder liner, etc. In order to prevent the piston rod and other slender parts from twisting or deformation, the use of cushion wood support balance when placed. (3) Disassemble in order.

How big gear pump need to use for 60*100 cylinder?

One cylinder size alone does not determine the size of the pump used. Choose the size of the pump, at least to know 1, the size of the load is how much, by the size of the load and the size of the cylinder and other conditions can be calculated the pressure required by the hydraulic system. 2. Speed of operation. From this speed and cylinder size, the required flow rate of the system is calculated. The relevant parameters of the pump can be selected by the pressure and flow rate to determine what kind of pump is required.