Release time:2023-11-19 14:06:01 Hits: Current position: Home > News

This article mainly introduces:

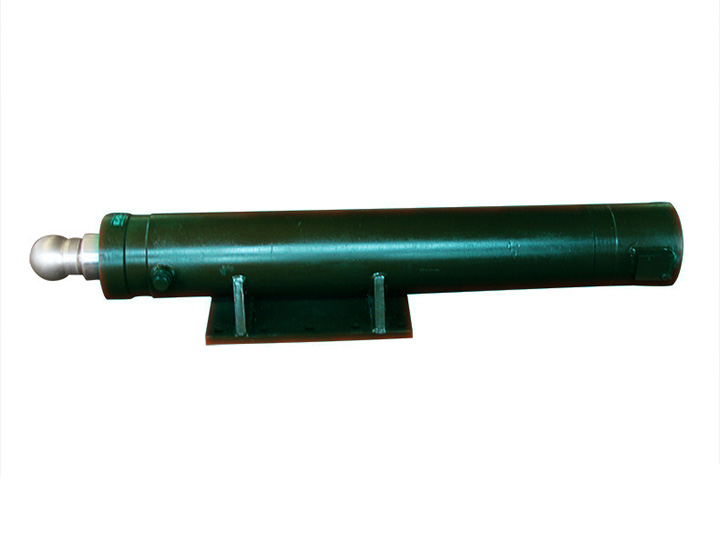

Slovakia hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Slovakia supporting cylinder,produced by Hengyu Group)

supporting cylinder are widely used in Slovakia,because of powerful torque,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed supporting cylinder for customers from Slovakia.

In order to ensure the service life of the supporting cylinder, the medium used must not be mixed with impurities and stolen goods, so as to avoid scratching the inner arm of the supporting cylinder, causing damage to the seal and causing leakage in the supporting cylinder. It is required that the filtration accuracy of the system is not less than 80μm, the oil pollution is strictly controlled, the hydraulic oil is kept clean, the performance of the hydraulic oil is regularly checked, and the necessary fine filtration or replacement of the new working hydraulic oil is carried out.

After the supporting cylinder is installed, lubricating grease should be added to the relative moving parts such as earring and middle hinge shaft before trial operation.

The supporting cylinder pipe should not be left behind when deburring at both ends after the fixed length processing. In addition, the placement of steel pipes near the site of welding pipeline operations is the cause of welding foreign objects. The pipes placed near the welding operation site should be sealed. It must also be noted that pipe fitting materials should be fully prepared on a dust-free workbench.

In recent years, the processing process of the supporting cylinder generally adopts the rolling method, which is a pressure finishing processing, which uses the cold plastic characteristics of the metal at room temperature, and uses the rolling tool to exert a certain pressure on the surface of the workpiece, so that the surface metal of the workpiece produces plastic flow, and fills in the low concave trough of the original residue, and the roughness value of the workpiece surface is reduced. Due to the plastic deformation of the rolled surface metal, the surface tissue is cold hardened and the grain is fine, forming a dense fiber, and forming a residual stress layer, and the hardness and strength are increased, thus improving the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

Why are the hydraulic cylinders out of sync? The reasons for the unsynchronous operation are as follows: 1, the deviation of the external load of the two cylinders, such as the different resistance and friction of the two cylinders will lead to imbalance. The displacement of the cylinder with low resistance will be larger. 2, the difference in internal friction, such as the difference between the piston and the cylinder of each cylinder, the friction between the piston rod and the seal causes the cylinder to be out of sync. 3. The different resistance of hydraulic oil along the pipeline of the two cylinders causes the cylinder to be out of sync. 4, the deviation of the control original adjustment causes the deviation of the flow to be out of sync, such as the use of an independent throttle valve for each cylinder will appear the difference in the flow of oil in and out of the oil affecting the synchronization of the two cylinders. 5. The cylinder support point of the supported part is initially different.

What is hydraulic cylinder? How to use hydraulic cylinder? what is the application of hydraulic cylinder?

Hydraulic cylinder is the hydraulic actuator that converts hydraulic energy into mechanical energy and does linear reciprocating movement (or swing movement). It is simple in structure and reliable in operation. When it is used to achieve reciprocating movement, the deceleration device can be eliminated, and there is no transmission gap, and the movement is smooth, so it is widely used in various mechanical hydraulic systems. The output force of the hydraulic cylinder is proportional to the effective area of the piston and the pressure difference between the two sides. The hydraulic cylinder is basically composed of cylinder body, cylinder head, piston, piston rod, sealing device, buffer device and exhaust device. Buffer device and exhaust device depending on the specific application, other devices are essential. Hydraulic cylinders are mainly used in machinery.