Release time:2023-11-24 08:39:13 Hits: Current position: Home > News

This article mainly introduces:

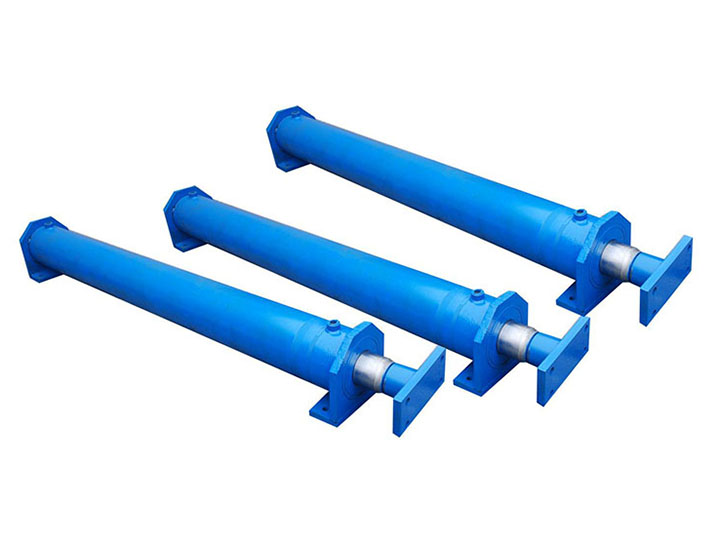

Sudan hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Sudan push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Sudan,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed push and pull the cylinder for customers from Sudan.

The pressure of the sliding surface of the push and pull the cylinder piston is too large, resulting in sintering. The piston tilts due to the weight of the piston rod, resulting in the phenomenon of non-stiffness, or the pressure of the sliding surface of the piston rises due to the action of the transverse load, which will cause sintering. In the design of the push and pull the cylinder must study its working conditions, the length of the piston and bushing and the size of the clearance must be fully paid attention to.

In recent years, the processing process of the push and pull the cylinder generally adopts the rolling method, which is a pressure finishing processing, which uses the cold plastic characteristics of the metal at room temperature, and uses the rolling tool to exert a certain pressure on the surface of the workpiece, so that the surface metal of the workpiece produces plastic flow, and fills in the low concave trough of the original residue, and the roughness value of the workpiece surface is reduced. Due to the plastic deformation of the rolled surface metal, the surface tissue is cold hardened and the grain is fine, forming a dense fiber, and forming a residual stress layer, and the hardness and strength are increased, thus improving the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

The coordination of the sliding parts of the push and pull the cylinder itself should not be too tight, the sealing friction force should not be too large, and H8 / f8 coordination should be selected between the piston rod and the guide sleeve; Check whether the size of the sealing ring is processed strictly according to the standard; If the V-shaped sealing ring is used, the sealing friction should be adjusted to a moderate degree.

How the cavitation of the push and pull the cylinder is formed: With the gradual rise of pressure, the gas in the oil will become bubbles, when the pressure rises to a certain limit value, these bubbles will break under the action of high pressure, so that the high temperature and high pressure gas will quickly act on the surface of the parts, resulting in cavitation of the push and pull the cylinder, resulting in corrosive damage to the parts.

Why is a light cylinder less productive than a heavy cylinder at the same oil pressure?

f=ps Under the same pressure, the larger the area, the greater the output, but the maximum pressure can not exceed the system engineering pressure of the cylinder!

Is rubber or polyurethane better for V-ring of hydraulic cylinder?

The hydraulic cylinder V-type seal ring is better with polyurethane, and chlorine rubber is used for various chemicals and high temperatures, especially when there are wear-resistant requirements, polyurethane rubber is needed. But the price of polyurethane rubber is much more expensive than the price of rubber. However, the V-ring material is most commonly used in nitrile and neoprene rubber, and natural rubber is used for sealing water and air. Butyl rubber is used for non-combustible hydraulic fluids and phosphate ester hydraulic fluids. The advantage is that the price is cheaper than the polyurethane material, and the disadvantage is that it is not wear-resistant and the anti-aging property is relatively poor.