Release time:2023-11-24 08:39:26 Hits: Current position: Home > News

This article mainly introduces:

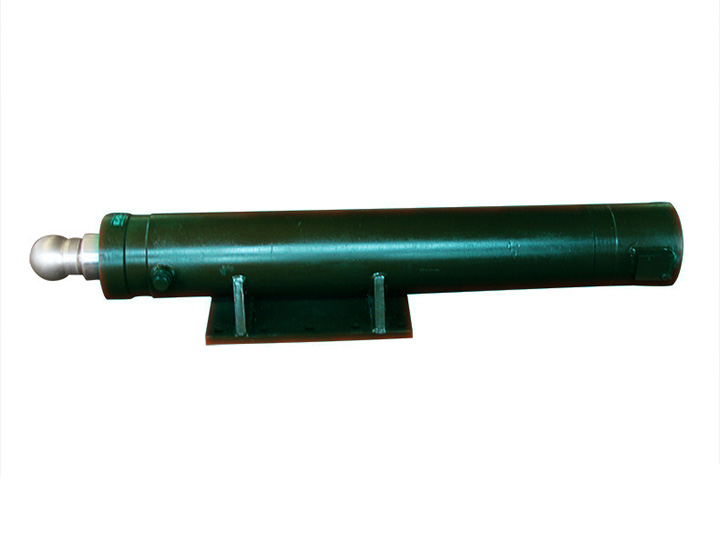

Singapore hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Singapore supporting cylinder,produced by Hebei Hengyu company)

supporting cylinder are widely used in Singapore,because of clever hydraulic energy conversion,excellent temperature resistance,high work efficiency.So our company has designed supporting cylinder for customers from Singapore.

In the process of using the supporting cylinder, sometimes such a problem will occur, the supporting cylinder can not act immediately after the instruction of the supporting cylinder action is issued, and it must be moved after a short time, or sometimes it can move and stop moving, showing that the operation is very irregular. The cause and elimination of this failure mainly include air in the oil supporting cylinder. Elimination method: exhaust through the exhaust valve. Check the piston rod reciprocating parts of the sealing ring for air inhalation, if so, replace the sealing ring.

When producing oil supporting cylinders, there are two processing processes, grinding and rolling, the latter is better than the former. Rolling machining is a kind of non-cutting machining, using the plastic deformation of the metal at room temperature, so that the micro roughness of the workpiece surface is flattened to achieve the purpose of changing the surface structure, mechanical characteristics, shape and size. Therefore, this method can achieve the two purposes of finishing and strengthening at the same time, which can not be done by grinding.

supporting cylinder spool stuck or valve hole blocked How to solve: When the flow valve or direction valve spool stuck or valve hole blocked, the supporting cylinder prone to misoperation or action failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium.

supporting cylinder piston sealing is best to use Yx ring, polyurethane and polytetrafluoroethylene sealing material combination, can significantly improve the sealing performance: (I), reduce friction resistance, no crawling phenomenon; (ii) Have good dynamic and static sealing, wear resistance, long service life; (iii) The installation groove is simple, and the disassembly is simple.

What is the cause of the deep scratch of the cylinder?

The following reasons can cause the cylinder to be scratched. 1: Hydraulic oil containing particulate impurities into the hydraulic cylinder, these particulate impurities stuck between the piston rod and the guide ring (or stuck between the piston and the inner wall of the cylinder), when the piston movement in the cylinder will scratch the piston rod, the phenomenon of the inner wall of the cylinder, the more particles, the larger the scratch marks the deeper and more obvious. 2: The body of the cylinder itself. Due to assembly or design reasons, the coaxial error between the piston rod, piston, cylinder, guide ring and other parts is too large, or the cylinder, piston rod straightness error is too large, so that the piston rod and the guide ring interference between the cylinder, this mechanical interference will certainly lose the piston rod or cylinder wall.

How to judge the failure of forklift hydraulic cylinder?

The common faults of the hydraulic cylinder of forklift truck are mainly crawling, insufficient thrust, working speed decline or even stop. Generally, crawling occurs at low speed. The main reason is that the air stored in the cylinder is not cleared. In addition, excessive or uneven mechanical friction can also cause crawling. Such as the piston and the piston rod different heart, the piston rod full length or local bending, the cylinder hole straightness is poor, the cylinder is drum shaped or has a large taper, the cylinder thin finish decline or produce hair, the cylinder installation accuracy is out of whack, the piston rod nuts at both ends of the screw too tight to make its concentricity is poor, the oil seal screw too tight friction is too large, will cause crawling.