Release time:2023-11-08 10:36:32 Hits: Current position: Home > News

This article mainly introduces:

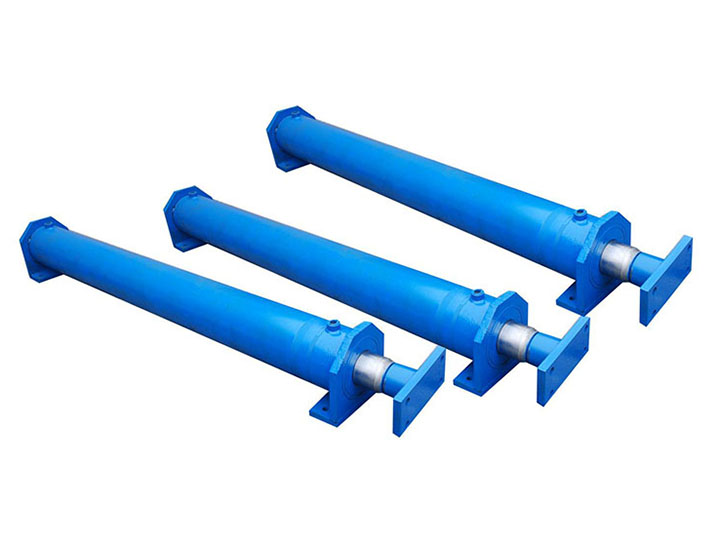

Norway hydraulic cylinder,hydraulic jig cylinder manufacturer,hydraulic jig cylinder

(Norway hydraulic jig cylinder,produced by Hengyu Group)

hydraulic jig cylinder are widely used in Norway,because of powerful torque,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed hydraulic jig cylinder for customers from Norway.

If air enters the hydraulic system, the hydraulic jig cylinder will not operate normally, mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced.

The pressure of the sliding surface of the hydraulic jig cylinder piston is too large, resulting in sintering. The piston tilts due to the weight of the piston rod, resulting in the phenomenon of non-stiffness, or the pressure of the sliding surface of the piston rises due to the action of the transverse load, which will cause sintering. In the design of the hydraulic jig cylinder must study its working conditions, the length of the piston and bushing and the size of the clearance must be fully paid attention to.

When the hydraulic jig cylinder is in use, ensure that the hydraulic jig cylinder and the surrounding environment should be clean. The tank should be sealed to prevent contamination. Pipelines and fuel tanks should be cleaned to prevent falling off the oxide sheet and other debris. Clean with lint-free cloth or special paper. Twine and binder should not be used as sealing materials. Hydraulic oil according to the design requirements, pay attention to the change of oil temperature and oil pressure. When there is no load, unscrew the exhaust bolt for exhaust.

How the cavitation of the hydraulic jig cylinder is formed: With the gradual rise of pressure, the gas in the oil will become bubbles, when the pressure rises to a certain limit value, these bubbles will break under the action of high pressure, so that the high temperature and high pressure gas will quickly act on the surface of the parts, resulting in cavitation of the hydraulic jig cylinder, resulting in corrosive damage to the parts.

Why is there noise in the hydraulic cylinder of the excavator lift arm?

There is no noise of a normal cylinder, check whether the throttle is ringing, or the mechanical part connected with it is ringing, and the mechanical part can be greased. If it can't be ruled out, disconnect the cylinder from the mechanical part and act alone to see what the situation is.

What is the cause of sound and vibration when the hydraulic cylinder is under load?

The main reason 1) may be that the load machinery has stuck phenomenon, and the resistance is large. 2) The hydraulic oil is not enough, or the filter is blocked by dirty things, and the oil is flooded. 3) There is a problem with the pump.