Release time:2023-11-30 10:59:56 Hits: Current position: Home > News

This article mainly introduces:

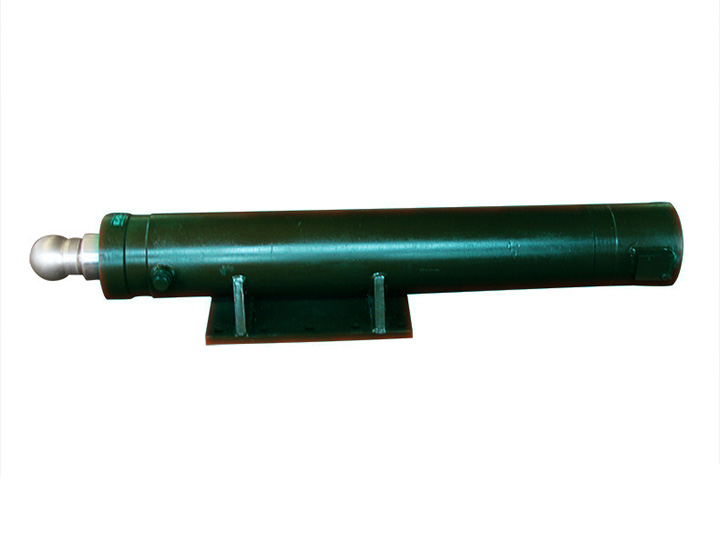

Italy hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Italy supporting cylinder,produced by Hengyu Hydraulic Cylinder Factory)

supporting cylinder are widely used in Italy,because of no need for deceleration device,long service life,smooth movement.So our company has designed supporting cylinder for customers from Italy.

Repair method of small range wear of oil supporting cylinder: 1. Use oxygen-acetylene flame to bake the scratched part (master the temperature, avoid surface annealing), bake the oil on the metal surface all the year round until no sparks splash; 2. The scratched part is treated with an Angle grinder, the grinding depth is more than 1 mm, and the groove is polished along the guide rail, preferably a dovetail groove. Scratch both ends of the drilling deeper, change the force situation; 3. Clean the surface with absorbent cotton dipped in acetone or anhydrous ethanol.

supporting cylinder head explanation: low pressure castings, medium and low pressure with HT300 gray iron, medium and high pressure with 35, 45 steel. When the supporting cylinder head itself is the guide sleeve of the piston rod, the supporting cylinder head is best cast iron. At the same time, brass, bronze or other wear-resistant materials should be fused on the guide surface. If the guide sleeve is pressed into the supporting cylinder head, the guide sleeve shall be wear-resistant cast iron, bronze or brass.

Most of the failure of the supporting cylinder is because there is a foreign body in the supporting cylinder into the failure of the supporting cylinder, the most problematic is that it is difficult to determine when the foreign body is into the supporting cylinder. After a foreign body enters, if the outer side of the sliding surface of the piston is equipped with a seal with a lip edge, then the lip edge of the seal can scrape the foreign body when working, which is beneficial to avoid scratching. However, the piston equipped with 0-shaped sealing ring has a sliding surface at both ends, and foreign bodies are sandwiched between this sliding surface, which is easy to form scars.

When the supporting cylinder needs to be disassembled for maintenance due to leakage and other faults, the piston should be moved to the bottom position of the supporting cylinder, and hard beating and sudden drop are strictly prohibited during disassembly.

How to calculate the hydraulic cylinder pressure, how much pressure can put up how much weight?

There is a formula for air pressure, hydraulic pressure, water pressure: F=P×S type: f-cylinder or hydraulic cylinder output, unit is Newton (N) P- pressure, unit is Mpa S- effective area, unit is square millimeter (mm2), note: is the effective area, in the hydraulic cylinder to subtract the cross-sectional area of the piston rod.

What's a minus 40 cylinder made of?

Construction with 1Cr18Ni9Ti, in low temperature conditions impact and tensile strength are very good, can withstand -100 degrees of low temperature, corrosion resistance, material price is not very high, more economic.