Release time:2023-12-01 11:06:33 Hits: Current position: Home > News

This article mainly introduces:

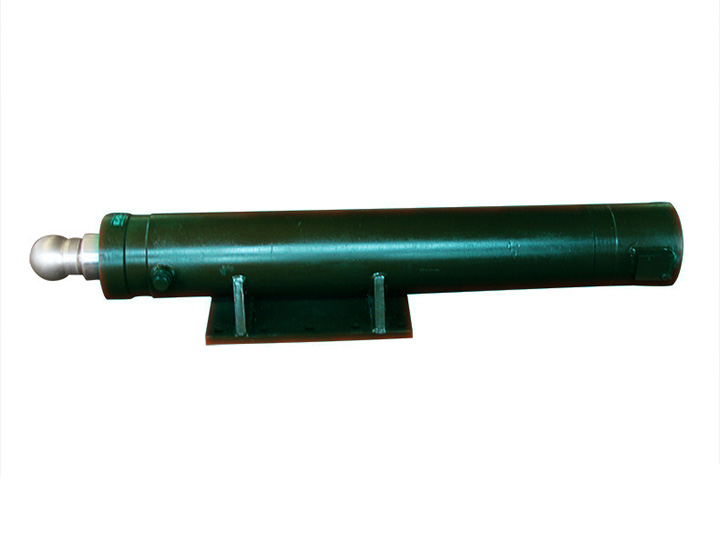

Republic of Lithuania hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Republic of Lithuania supporting cylinder,produced by Hengyu Hydraulic Cylinder Factory)

supporting cylinder are widely used in Republic of Lithuania,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed supporting cylinder for customers from Republic of Lithuania.

What kind of process is used in the supporting cylinder to make high-quality supporting cylinder products: the body is the main component of the supporting cylinder, mining single pillar, hydraulic support, gun tube and other products, and its processing quality directly affects the life and reliability of the entire product. Body processing requirements are high, the internal surface roughness requirements are Ra0.4 ~ 0.8&um, the coaxiality, wear resistance requirements are strict. The basic feature of body is deep hole processing, which has always troubled the processing personnel. The supporting cylinder products of our company mainly use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface micro-cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the body can be improved. The correct rolling process of the supporting cylinder block: broaching block - fine boring block - grinding block. The rolling method is: broaching block - fine boring block - rolling block, the process is 3 parts, but the time is compared: grinding 1 meter of the block is about 1-2 days, rolling 1 meter of the block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the supporting cylinder increases by 25%. If the service life of the supporting cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. supporting cylinder misoperation or operation failure may be caused by the following reasons, you can start from these aspects of the investigation: (1) spool stuck or valve hole blocked. When the spool of the flow valve or direction valve is stuck or the valve hole is blocked, the supporting cylinder is prone to misoperation or operation failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium. (2) The piston rod and supporting cylinder are stuck or the supporting cylinder is blocked. At this time, no matter how to manipulate, the supporting cylinder does not move or moves very little. At this time, check whether the piston and piston rod seal is too tight, whether it enters the dirt and gum deposits: whether the shaft line of the piston rod and the supporting cylinder is in the center, whether the wearing parts and seals are invalid, and whether the load is too large.

How the cavitation of the supporting cylinder is formed: With the gradual rise of pressure, the gas in the oil will become bubbles, when the pressure rises to a certain limit value, these bubbles will break under the action of high pressure, so that the high temperature and high pressure gas will quickly act on the surface of the parts, resulting in cavitation of the supporting cylinder, resulting in corrosive damage to the parts.

After the supporting cylinder is installed, lubricating grease should be added to the relative moving parts such as earring and middle hinge shaft before trial operation.

The wear of the hard chromium plating layer of the supporting cylinder is mostly caused by the grinding of the friction iron powder of the piston, and the wear is faster when there is water in the middle. Corrosion caused by the contact potential difference of the metal only occurs in the part of the piston contact, and the corrosion occurs in a point pattern. As mentioned above, when there is moisture in the middle, it will promote the development of corrosion. Compared with castings, the contact potential difference of copper alloy is higher, so the corrosion degree of copper alloy is more serious.

How to limit cylinder push rod rotation?

In general, the push-rod rotation can be limited after the push-rod is connected to the pushed mechanism. For example, the push rod is hinged with the push mechanism, or the push mechanism itself is guided, which can limit the rotation of the push rod.

How to control the speed of the hydraulic cylinder?

The speed of the hydraulic cylinder is only related to the flow, so the control speed is to control the flow of the hydraulic oil, which is generally adjusted by the throttle valve in the system.