Release time:2023-12-01 11:06:42 Hits: Current position: Home > News

This article mainly introduces:

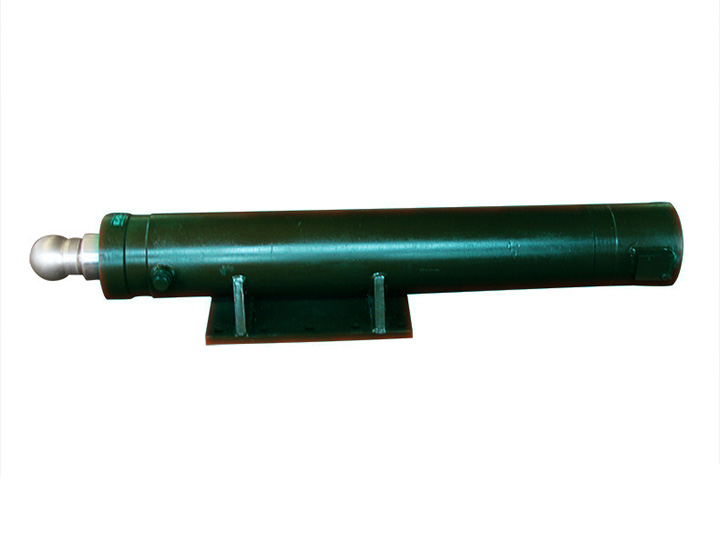

Burma hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Burma supporting cylinder,produced by Hengyu Group)

supporting cylinder are widely used in Burma,because of smooth movement,no need for deceleration device,long service life.So our company has designed supporting cylinder for customers from Burma.

The supporting cylinder should not be mixed with foreign objects during assembly, which will cause scars. Before the total assembly of the supporting cylinder, all parts must be fully removed and cleaned. When the parts are installed with burrs or dirt, foreign objects are easily embedded into the surface of the supporting cylinder wall due to the stiffness and the weight of the parts, causing scars.

The repair method of the supporting cylinder: the repair of the supporting cylinder must use brush plating. This is because this repair method can be carried out on site, and the repair effect is good. In this way, loading and transportation can be eliminated to shorten the repair time and improve work efficiency. In addition, the coating obtained by brush plating has good binding force and will not have obvious boundaries. Moreover, the repair surface has high hardness and good wear resistance.

Before the supporting cylinder is removed, the relief valve should be loosened to reduce the pressure of the hydraulic circuit to zero, and then the power supply should be cut off to stop the hydraulic device. After loosening the oil port piping, the oil plug should be applied to plug the oil port.

When installing the supporting cylinder, the axial ends of the supporting cylinder cannot be fixed. Due to the effect of liquid pressure and thermal expansion in the supporting cylinder, there is axial expansion. If the two ends of the supporting cylinder are fixed, all parts of the supporting cylinder will be deformed. When disassembling the supporting cylinder, it is strictly forbidden to hammer the supporting cylinder and the piston surface, such as the supporting cylinder hole and the piston surface is damaged, do not allow sandpaper grinding, to use a fine oil stone carefully grinding. The clearance between the guide sleeve and the piston rod should meet the requirements.

What material should be selected to seal the cylinder?

The choice of material for sealing is related to the working environment, strength, and medium of your equipment.

What is the reason why the hydraulic cylinder is not good at lifting?

There may be several situations 1, whether the slow one is worn 2, whether there is air in the slow cylinder 3, if the two cylinders are supplied by the same oil port, whether the slow joint is blocked (some processing residue will reach a certain oil port under a certain coincidence condition, This situation will not happen if it is not necessarily good before) 4, the oil seal in the slow cylinder leaks, causing the feed oil to leak from the return oil end. Point 4 is most likely because it is invisible and a technical failure. If it is a dual oil feed (separate oil feed), it is also necessary to check the oil supply system and the oil return system (valve type).