Release time:2023-12-12 10:13:38 Hits: Current position: Home > News

This article mainly introduces:

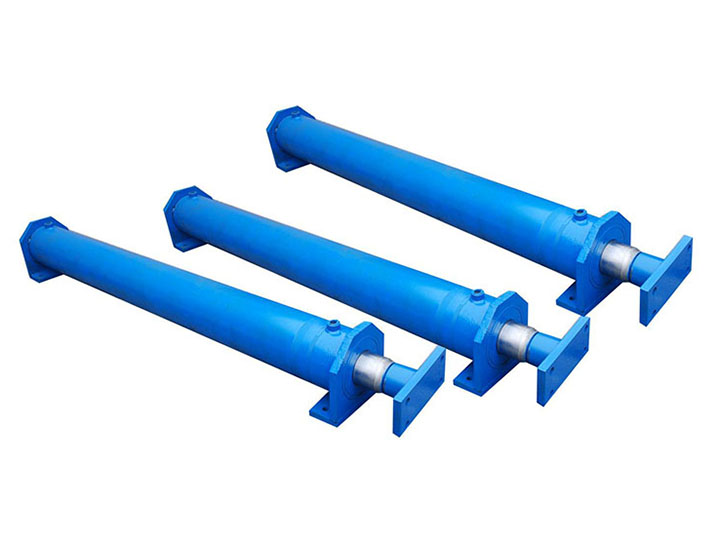

Ireland hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Ireland push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Ireland,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed push and pull the cylinder for customers from Ireland.

If the push and pull the cylinder piston rod is found to be worn, it can be brushed and plated first, then ground, and finally adjust the mating accuracy of the piston rod and the guide sleeve. At this time, the guide sleeve can be properly redrilled or the guide sleeve can be re-turned. When making the above repairs, remember to replace various rubber seals in time.

Analysis of commonly used seals: The wear ring and slip ring commonly used on the push and pull the cylinder are generally made of polytetrafluoroethylene + graphite, because pure polytetrafluoroethylene is easy to produce plastic creep, which is only suitable for low pressure and low wear resistance conditions. If the sealing ring used is a composite material formed after adding graphite filler, the performance can be effectively improved, the ability to resist plastic creep is increased by 2 to 3 times, the initial deformation caused by the load is reduced by 30 to 60% : the rigidity is increased by 2 to 3 times: the dimensional stability under heat is increased by 2 times, and the hardness is increased by l0 to 15%.

When the push and pull the cylinder wear is serious, you can try to use an alloy scraper to shave grooves with a depth of more than 1mm on the surface of the slip injury, then clean the grooves with acetone, apply the adjusted TS311 anti-wear repair agent on the polished surface with the push and pull the cylinder inner diameter copying plate, and scrape it flat vigorously to ensure compaction and higher than the inner surface of the push and pull the cylinder. After curing, polish to leave a finishing margin. Finally, the overall size, shape tolerance and roughness of the push and pull the cylinder can meet the requirements by grinding. However, the life and reliability of this repair push and pull the cylinder are not high.

After chrome plating of the piston rod of the push and pull the cylinder, the surface flatness is not fully treated: After chrome plating of the piston rod surface, the method of post-plating polishing should be changed to post-plating polishing. Although it is necessary to increase the thickness of the coating before grinding (generally increased by about 0.02 in the diameter direction), it can remove chrome plating defects well, and test the binding force of the coating. In addition, due to the micro-roughness of the grinding surface, the trough can store lubricating oil, which can improve the wear resistance and extend the service life.

How to select the propulsion cylinder according to the shield attitude, cylinder stroke, shield tail clearance and other factors?

Generally, the shield machine will be equipped with the corresponding cylinder. Soil pressure balancing machine, mud water balancing machine have the corresponding cylinder, there will be no insufficient cylinder force. In the jacking process of the pipe jacking machine, there are certain requirements for the jacking force of the cylinder.

What is the role of the cylinder on the plastic mold? The oil cylinder plays a great role in the mold, one is that the core distance is very large, or because of the mechanism of the product, only the oil cylinder is reasonable or more cost saving. Let the side core be extracted before opening the mold. Hot runner is mainly based on the product, sometimes customers require to use hot runner, the price is more expensive, but there are many benefits. It can save raw materials and shorten the molding cycle.