Release time:2023-12-18 10:57:11 Hits: Current position: Home > News

This article mainly introduces:

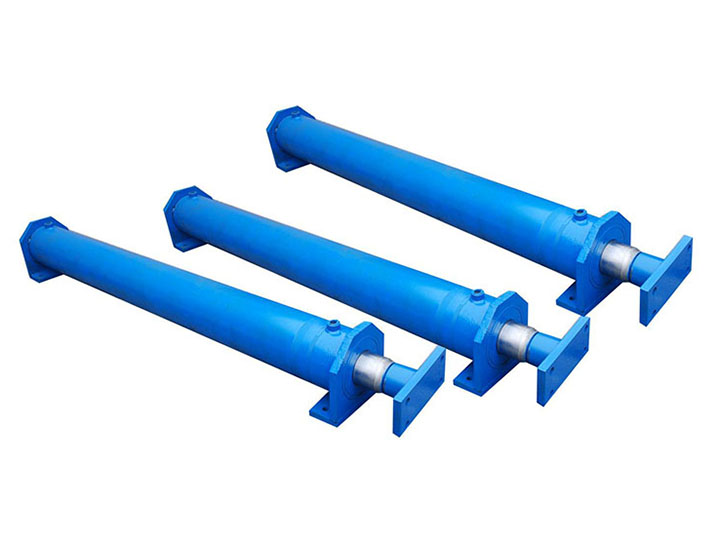

Slovenia hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Slovenia push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Slovenia,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed push and pull the cylinder for customers from Slovenia.

push and pull the cylinder spool stuck or valve hole blocked How to solve: When the flow valve or direction valve spool stuck or valve hole blocked, the push and pull the cylinder prone to misoperation or action failure. At this time, the contamination of the oil should be checked; Check whether dirt or colloidal deposits are stuck in the spool or blocking the valve hole; Check the wear of the valve body, clean and replace the system filter, clean the fuel tank, and replace the hydraulic medium.

When the push and pull the cylinder wear is serious, you can try to use an alloy scraper to shave grooves with a depth of more than 1mm on the surface of the slip injury, then clean the grooves with acetone, apply the adjusted TS311 anti-wear repair agent on the polished surface with the push and pull the cylinder inner diameter copying plate, and scrape it flat vigorously to ensure compaction and higher than the inner surface of the push and pull the cylinder. After curing, polish to leave a finishing margin. Finally, the overall size, shape tolerance and roughness of the push and pull the cylinder can meet the requirements by grinding. However, the life and reliability of this repair push and pull the cylinder are not high.

The push and pull the cylinder should be vented: when the push and pull the cylinder is installed or parked for a long time to work again, the air will penetrate into the push and pull the cylinder and the pipeline system. In order to prevent the abnormal phenomenon of crawling, noise and heating of the actuator, the air in the push and pull the cylinder and the system should be discharged. In order to facilitate the removal of air deposited in the push and pull the cylinder, the oil is best entered and discharged from the highest point of the push and pull the cylinder. push and pull the cylinders that require higher motion stability are often equipped with exhaust plugs at both ends. Before working, unscrew the exhaust plug to make the piston go back and forth several times without load in the whole stroke, and the air can be discharged through the exhaust plug. After the air is drained, tighten the exhaust plug before working.

In the case of serious wear on the inner surface of the push and pull the cylinder, or when there is a deep longitudinal tensile mark, it should be mapped according to the physical object and re-produced by the professional manufacturer according to the push and pull the cylinder manufacturing process for replacement. The push and pull the cylinder can also be repaired with TS311 antiwear repair agent. TS311 anti-wear repair agent is mainly used for the repair of worn and slipped metal parts.

What is the difference between hydraulic cylinder self-adjusting buffer and adjustable buffer?

If it is the buffer device inside the cylinder, then there are 4 basic forms, cylindrical buffer device, conical buffer device, variable throttle and adjustable flow groove. The biggest difference between the first three and the latter is that the latter can be adjusted through the external thimble to change the buffer strength, the first three mainly rely on the buffer device and buffer groove form to achieve the buffer (among them, the first type of buffer strength will not change, and the buffer strength of the two and three forms of buffer devices can be gradually increased).

What is the cause of the deep scratch of the cylinder?

The following reasons can cause the cylinder to be scratched. 1: Hydraulic oil containing particulate impurities into the hydraulic cylinder, these particulate impurities stuck between the piston rod and the guide ring (or stuck between the piston and the inner wall of the cylinder), when the piston movement in the cylinder will scratch the piston rod, the phenomenon of the inner wall of the cylinder, the more particles, the larger the scratch marks the deeper and more obvious. 2: The body of the cylinder itself. Due to assembly or design reasons, the coaxial error between the piston rod, piston, cylinder, guide ring and other parts is too large, or the cylinder, piston rod straightness error is too large, so that the piston rod and the guide ring interference between the cylinder, this mechanical interference will certainly lose the piston rod or cylinder wall.