Release time:2023-11-10 08:35:26 Hits: Current position: Home > News

This article mainly introduces:

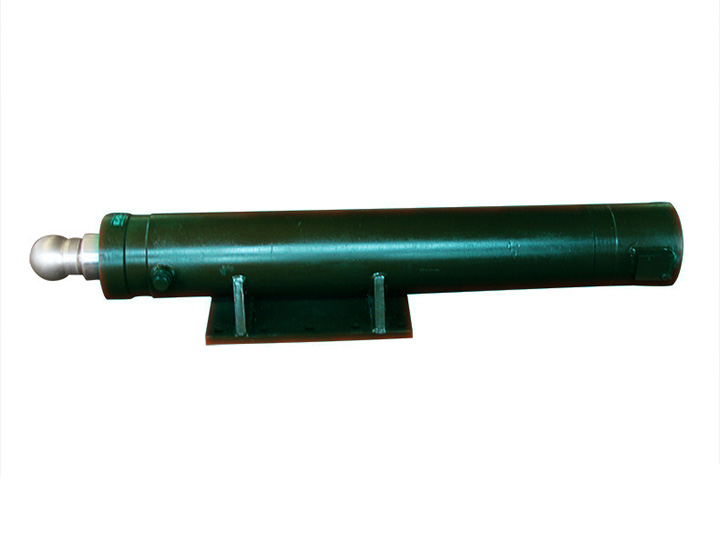

Cote d 'Ivoire hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Cote d 'Ivoire supporting cylinder,produced by Hengyu Hydraulic Co., Ltd)

supporting cylinder are widely used in Cote d 'Ivoire,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed supporting cylinder for customers from Cote d 'Ivoire.

The material, shape and compression of the supporting cylinder seal have a great impact on the service life and work efficiency of the supporting cylinder. In addition to requiring a reliable seal, it should also have a long service life and less friction loss. At present, there are many seal manufacturers in the country, and it is also crucial to choose high-quality seals with reliable and stable quality.

The pressure, temperature, medium and speed of different types of seals are not the same, water-ethylene glycol medium (HFC) can not be sealed with polyurethane, it can only use rubber seal; When the supporting cylinder is running fast, it must be sealed with slip ring, such as Sterseal, Glairing, GD1000K, TDI, etc., when the running speed is slow, Yx, U, V combination seals can be used; Fluorine rubber seal is used in high temperature and high pressure environment; When the running speed is fast, the buffer sleeve and buffer valve must be considered.

In order to ensure the service life of the supporting cylinder, the hydraulic system must be set up effective filtration to prevent pollution, the cleanliness of the oil should meet the ISO4406 standard, and the quality of the filtration should also meet the corresponding standards in ISO. The grade requirements of the filter are performed according to the actual working conditions of the system, but the minimum requirements are not less than 19/15 in ISO4406, that is, 24μ (β10≥75) in ISO4572.

supporting cylinder use should try to avoid sealing belt into the supporting cylinder. As a simple sealing material, polytetrafluoroethylene plastic sealing tape is often used in installation and inspection, and if the winding method of the linear and ribbon-shaped sealing material is wrong, the sealing tape will be cut off and enter the supporting cylinder. The wire belt seal will not have any effect on the winding of the sliding part, but it will cause the check valve of the supporting cylinder to fail to operate or the buffer regulating valve can not be adjusted to the end. For the circuit, it may cause the action of the reversing valve, the relief valve and the reducing valve to fail.

What do cylinder internal leakage and external leakage mean?

Internal leakage means that the piston seal in the cylinder is not strict, there is a leak between the two chambers of the cylinder, the oil is still in the cylinder, and the external leakage is that the oil leaks to the outside of the cylinder.

What are the causes of hydraulic cylinder oil leakage?

First, between the piston rod and the guide sleeve: 1, the cylinder force is not good, there is a radial force between the piston rod and the guide sleeve there is a partial load, so that the oil seal is worn early, causing oil leakage. 2. The ambient temperature of the piston rod is high, especially radiant heat, and the oil seal aging is fast. 3. Whether the oil seal is selected correctly; Check whether the oil seal is damaged during installation. 4, guide sleeve and piston rod matching tolerance is correct. Second, between guide sleeve and cylinder: 1. Whether the O-ring on the guide sleeve is installed correctly, pay special attention to the O-ring can not "roll", especially some O-rings are die-pressed with a die-closing line. Third, common problems: 1, guide sleeve, cylinder, piston rod concentricity is poor. Fit tolerance is correct.